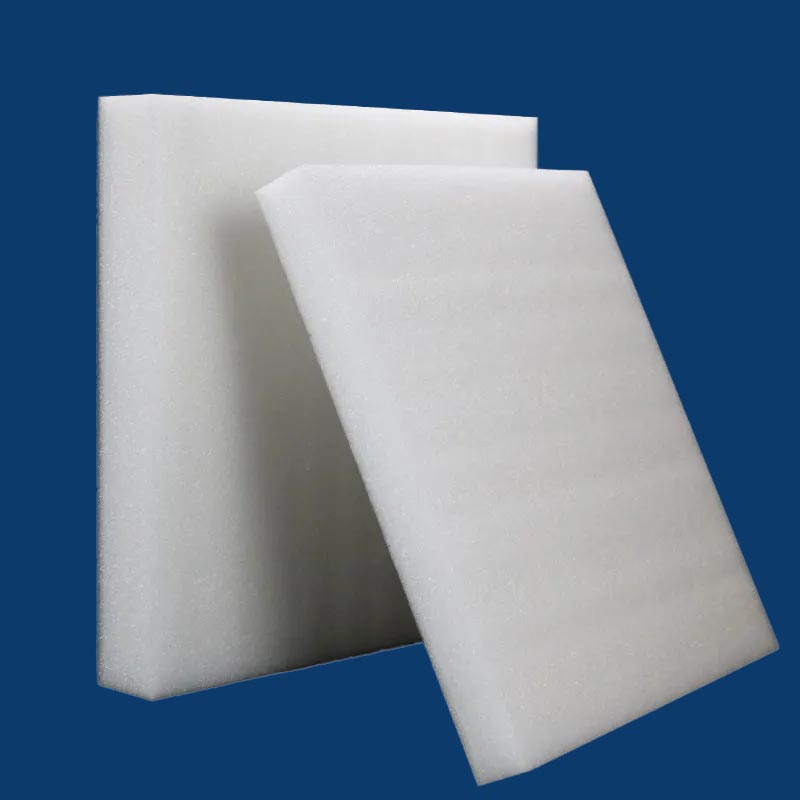

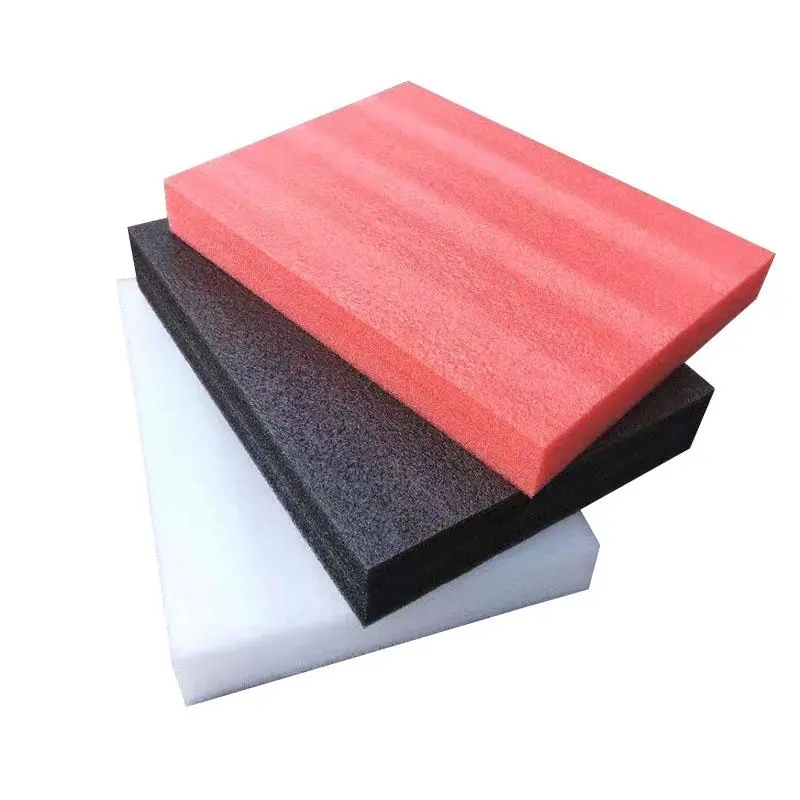

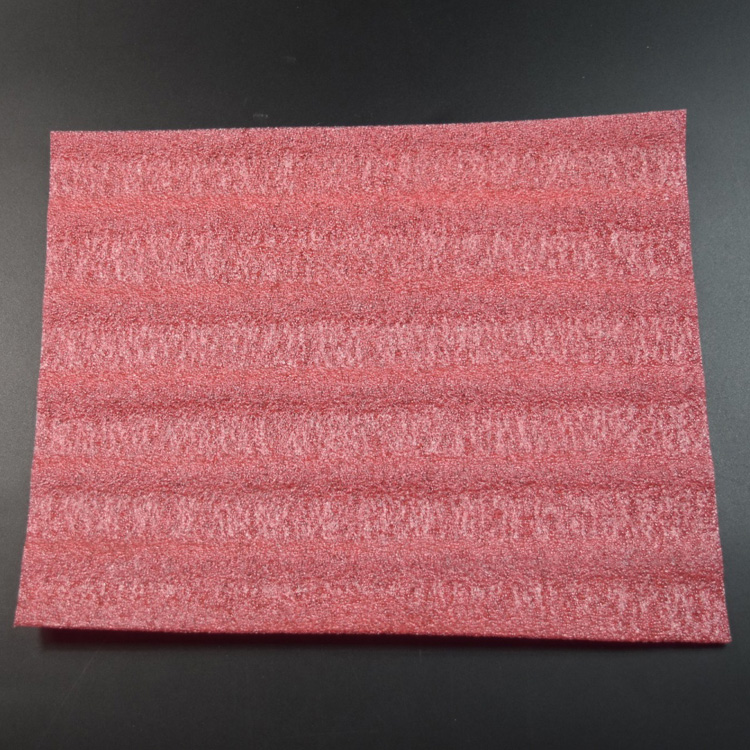

VCI (Volatile Corrosive Inhibitor) Foam

By wrapping around the materials being shipped, VCI foam protects multitude of metals from corrosion, humidity and pollution. Mono-ionic VCI layers do not affect electrical/optical and/mechanical surface properties and provides safety and protection for up to 24 months. An ideal material to be used inside poly bag, aluminum foil, laminated bag and also for packing electrical and electromechanical control panels, electrical fixtures, security alarms, electrical motors, switchgear and relay cabinets, junction fuse boxes, bus bars, marine/ aerospace/ military instruments, computer and telecom equipment, scientific instruments, medical equipment/ devises, heavy machinery, tools and spare parts in power generation units etc.

Variants

- Customized

Density

- 19 to 40 Density

Usage Area

Electronic / Electrical Based

- Computer

- X-ray equipment and X-ray Films

- Electronic equipment and Components

- Electrical Application and Components

- Audio / Video equipment

Fragile Based

- Marble

- Granites and Tiles

- Glass and Glass wares

Engineering Industries

- Automobiles

- Handicrafts & Garments Industry

- Home Appliances

- Life Saving Jackets

- Expansion Joint Fillers

- Waterproofing of Terrace/Roofs

- AC Insulation Pads

- Carpet Underlay

Engineering Industries

- Automobiles

- Handicrafts & Garments Industry

- Home Appliances

- Life Saving Jackets

- Expansion Joint Fillers

- Waterproofing of Terrace/Roofs

- AC Insulation Pads

- Carpet Underlay

Manufacturer

- IRETEX PREMIER INDIA PVT LTD

FAQs

1. What is VCI Foam, and how does it work?

VCI Foam (or Volatile Corrosive Inhibitor Foam) is a vapor-phase corrosion inhibitor release agent that deposits protective metal surface coatings subsequently oxidation and rust do not occur. With this method, no need for bulky oils or coating.

2. What types of metals can VCI Foam protect?

IRE-TEX Premier's VCI Foam consists of the most efficient process for protecting various types of metals, the package prevents the corrosive attacks of not only iron but with almost all multimetal mixes, thus providing them with multi-metal protection functionality.

3. Is the VCI Foam environmentally friendly and safe to use?

The VCI Foam of IRE-TEX Premier is not only environmentally friendly but also does not contain such harmful chemicals. It is utilized as a vibration control, vibration isolation, and energy-absorbing device to comply with environmental safety regulations.

4. Can VCI Foam be customized for specific packaging needs?

Of course. Customization can be achieved with IRE-TEX Premier's VCI products when they are used by a packaging manufacturer or service provider as the solution for the protection needs of your products.

5. Is VCI Foam packaging reusable?

Yes, IRE-TEX Premier's VCI Foam packaging is reusable. It can then be cleaned properly and stored in a dry storage facility when not in use to make sure it stays effective and inspected for any damage or loss of VCI properties before reuse of the foam.

Other Products You Might Like:

Industrial Products | Bubble Mailers / Bubble Envelopes | Poly Bubble Mailers / Poly Bubble Envelopes | Packing Rolls | EPE Buffers / Fabrications | EPE Foam Sheet | EPE Foam Roll | Air Bubble Film Roll | Anti- static / ESD Rolls and Sheets | VCI (Volatile Corrosive Inhibitor) Foam